Products Details

Tile Adhesive – ACT TAD 103

ACT TAD 103 is the polymer based cementitious material in powder form. It is factory prepared blend of carefully selected raw materials and in proportion as per the IS guidelines and standards. It is designed to use with water to produce superior strength. ACT TAD 103 is used for fixing varieties of tiles on interior and exterior floors and walls. It is easy to use with improved bond and maintains cleanliness at work place at the time of execution.

Uses

ACT TAD 103 is especially for interior and exterior floor and wall installations of all types of ceramic tile, vitreous, semi-vitreous tile, glass mosaic tiles, precast terrazzo, etc. over concrete and on a variety of substrates.

Advantages

-

Easy to apply, single component just add water.

-

Time & labor saving.

-

High strength, polymer modified.

-

Bonds on various substrates.

-

Better quality due to accurate mixing proportion.

-

Water resistant

-

Reduces wastage.

-

It ensures quality and enhances durability, since it is free from clay or silt in sand.

- Packaging: 40 Kg bag

- Colour: Grey.

Coverage

Approx coverage is 95-100 sft per 40kg bag for average bed of 3mm.

-

Coverage will vary depending on trowel notch size, type and size of tile and substrate smoothness and evenness.

Shelf Life

Factory sealed bags of this product are good for three (3) months* if stored off the ground in a dry area under controlled atmosphere.

-

High humidity will reduce the shelf life of bagged product

Limitations

These mortars are not replacements for waterproof membranes. When a waterproof membrane is required use specific product.

TECHNICAL DATA

-

Working Properties

-

-

Appearance & Color

Greyish granular powder

-

Binder

Cement

-

Aggregate

Graded sand

-

Additives

Special additives for better strength, binding, durability, strength and efficiency.

-

Bulk density

1500 - 1600 Kg/cum.

-

Pot life

1-2 hours approx.

-

Performance properties

-

-

Compressive strength (MPA)

≥5 MPA at 28 days

-

Specifications are subject to change without notification. Results shown are typical but reflect test procedures used. Actual field performance will depend on installation methods and site conditions

INSTALLATION

-

Ensure that the surface to be tiled is clean and free of all dirt, oil, grease, concrete sealers etc. to avoid weak bonding. Rough or uneven concrete surfaces should be made smooth to provide better finish. In case of dry surface, water should be sprinkled to make the surface moist.

-

Use 40kg of ACT TAD 103 with Approx. 10-12 litres or appropriate amount of potable water. Take water in the container and slowly add the powder into the water while mixing by hand or with a slow speed mixer to a smooth, trowelable consistency. Allow adhesive to slake for 5-10 minutes. Adjust consistency if necessary. Remix and apply with the proper sized notched trowel.

-

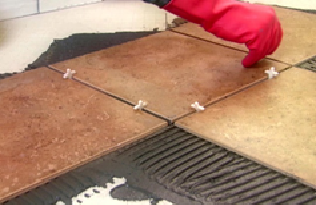

Apply adhesive to the substrate as well as on the back of the tile with the flat side of the trowel, pressing firmly to work into surface. Comb on additional adhesive with the notched side. Use the proper sized notched trowel to ensure full bedding of the tile. Place tiles into wet, sticky adhesive and beat in using a beating block and rubber mallet to imbed tile and adjust level. Check adhesive for complete coverage by periodically removing a tile and inspecting bedding adhesive transfer onto back of tile. Use of spacers is recommended to provide grout joints between tiles / stones. The joint width shall be as per the recommendation of architect / engineer. Remove the spacers when the adhesive is set firm. If adhesive is skinned over (not sticky), remove and replace with fresh adhesive.

-

Clean tools and containers with water while mortar is fresh. Clean tools after more than 20 minutes break.